Understanding the difference between a warehouse control system and a warehouse management system is critical for companies looking to streamline operations, cut costs, and keep pace with customer demands. In this blog, we’ll explain what a WCS is, how it differs from a WMS, and why pairing WCS software with WMS—or an orchestration layer—can transform warehouse efficiency.

What Is a Warehouse Control System (WCS)?

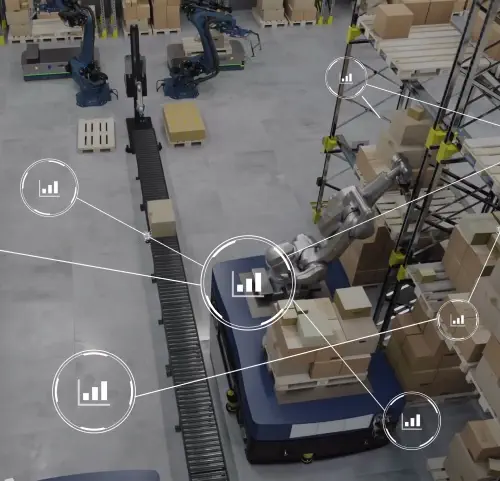

A warehouse control system (WCS) is specialized software application designed to direct and coordinate the activity of automated material handling equipment inside the warehouse. Unlike a WMS, which manages inventory data and fulfillment processes, WCS software focuses on the real-time execution layer—ensuring that conveyor systems sorters, robotics, and automated storage systems work in sync.

You may also see the term warehouse execution system (WES). In many operations, WES extends WCS-style control with additional routing, balancing, and work release logic between the WMS and automation.

Key functions include:

- Equipment control: Directing conveyors, AGVs, and robotic systems.

- Task execution: Managing picking, sorting, and routing decisions in real time.

- System integration: Bridging the WMS (and, where used, WES) with physical automation equipment.

- Monitoring & reporting: Tracking equipment performance and resolving issues quickly to minimize downtime.

In short, a WCS (or warehouse execution system WES where applicable) turns high-level instructions into precise, real-time actions so automated warehouses run smoothly.

Warehouse Control System vs. Warehouse Management System

While a warehouse control system (WCS) and a warehouse management system (WMS) are both critical to warehouse operations, they serve very different purposes. Many businesses mistakenly believe one replaces the other, but in reality, they are complementary systems that work best together.

What a WMS Does

A warehouse management system focuses on the strategic and operational management of inventory and fulfillment, typically sitting alongside enterprise resource planning (ERP). Its main functions include:

- Tracking inventory levels across the warehouse in real time.

- Managing order fulfillment, including picking, packing, and shipping.

- Generating reports and analytics for better decision-making.

- Optimizing labor by assigning tasks to staff efficiently.

- Integrating with enterprise resource planning for finance, purchasing, and master data alignment.

In short, a WMS provides the “brains” of the warehouse, telling staff and systems what needs to happen to fulfill orders accurately and efficiently.

What a WCS Does

A warehouse control system, on the other hand, manages the real-time control of automated equipment. Instead of focusing on data or inventory planning, it ensures that automation—such as conveyors, sorters, robotics, or automated storage and retrieval systems (AS/RS)—operates without delays or conflicts. Key functions of a WCS include:

• Directing conveyors and robotics for smooth material flow.

• Routing items to the correct stations for picking or packing.

• Monitoring equipment to prevent bottlenecks.

• Providing real-time feedback to the WMS about execution status.

Key Differences Between WCS and WMS

- Scope: WMS manages inventory and workflows, while WCS manages machines and real-time execution.

- Decision-making: WMS makes high-level decisions (e.g., what order to pick first), while WCS translates those decisions into machine actions (e.g., sending a carton to the correct lane).

- Users: WMS is typically used by warehouse managers and staff, while WCS works behind the scenes with automation equipment.

Why Many Businesses Need Both

For warehouses with automation, relying on just a WMS isn’t enough. A WMS can tell the warehouse what to do, but without a WCS, there’s no system ensuring equipment executes those instructions properly.

By combining the two:

- The WMS handles the data and workflow layer (orders, inventory, reporting).

- The WCS ensures flawless execution at the equipment layer (movement, sortation, automation).

Together, they create a powerful, synchronized system that reduces errors, speeds up fulfillment, and ensures maximum productivity.

Benefits of WCS Software

Implementing WCS software can transform how efficiently a warehouse operates—especially where automation is critical. While a WMS manages data and order workflows, a WCS (or warehouse execution system WES in some environments) ensures every piece of automated equipment works in harmony.

Improved Speed and Accuracy

A WCS coordinates the flow of goods across conveyors, robotics, and automated systems in real time, minimizing delays and misroutes so orders move faster with fewer mistakes.

Seamless Integration with Automation Technologies

A WCS acts as the bridge between automation and the WMS (and can complement WES), making sure machines follow warehouse instructions precisely and efficiently.

Reduced Downtime and Bottlenecks

When equipment slows or fails, the WCS detects issues immediately and reroutes tasks to keep operations running.

Real-Time Decision-Making

Unlike a WMS that plans ahead, WCS adjusts execution second by second based on what’s happening on the floor.

Enhanced Efficiency and ROI

By optimizing flow and equipment utilization, WCS software helps increase throughput and lower labor costs.

When Does Your Business Need a WCS?

Not every warehouse requires a warehouse control system (WCS). Smaller operations that rely mostly on manual labor and basic inventory tracking may find a warehouse management system (WMS) sufficient. However, as soon as automation becomes a key part of operations, the need for a WCS becomes clear.

Here are the situations where businesses benefit most from adding a WCS:

High-Volume Order Fulfillment Centers

If your warehouse processes thousands of orders daily, manual coordination alone can’t keep up. A WCS ensures that automated conveyors, sorters, and robotics operate at maximum efficiency, reducing delays during peak demand.

Warehouses with Advanced Automation

Businesses that have invested in conveyors, automated storage and retrieval systems (AS/RS), robotic picking, or AGVs need a WCS to act as the “traffic controller.” Without one, equipment may operate inefficiently, causing bottlenecks and downtime.

Businesses Scaling Rapidly

When a company is growing and order volume is increasing, the warehouse must adapt quickly. A WCS provides the scalability needed to handle more complex automation requirements without sacrificing speed or accuracy.

Operations That Require Real-Time Control

Industries like e-commerce, retail distribution, and 3PLs thrive on speed and accuracy. A WCS enables real-time decisions that keep goods moving and ensures orders are routed correctly to meet customer expectations.

WCS + WMS: A Powerful Combination

While a warehouse management system (WMS) and a warehouse control system (WCS) can function independently, their true strength comes when they work together—and, in some operations, with a warehouse execution system WES coordinating work release between the two. A WMS ensures inventory and order data is accurate, while a WCS makes sure automation executes those orders seamlessly.

How They Complement Each Other

• WMS: Decides what needs to happen (which orders to fulfill, what inventory to allocate, when tasks should be scheduled).

• WCS: Executes those instructions in real time by managing the equipment that moves goods through the warehouse.

Together, the two systems create a closed loop: the WMS provides high-level strategy and oversight, while the WCS ensures flawless physical execution.

The Role of Orchestration Software

For many businesses, running both systems separately can become costly and complex. That’s where orchestration software comes in. By integrating the functionality of a WMS and WCS into a single platform, businesses gain:

- Unified visibility across inventory, workflows, and equipment.

- Reduced costs by eliminating the need for multiple software systems.

- Simplified IT management and faster implementation.

How Supply Chain Orchestrator Simplifies WMS and WCS Needs

Managing both a warehouse management system (WMS) and a warehouse control system (WCS) separately can be costly, complex, and overwhelming for small and mid-sized businesses. That’s why Supply Chain Orchestrator was designed to bring these capabilities together in a single, powerful, and easy-to-use platform.

All-in-One Logistics Platform

Unlike traditional software that forces you to manage multiple systems, Supply Chain Orchestrator unifies:

- Cloud WMS – for inventory, order management, and reporting.

- Workflows – to automate tasks, notifications, approvals, and more.

- Mobile WMS App – to give staff real-time access anywhere in the warehouse.

- Customer Portal – for seamless communication and visibility.

- Dimensioning System – to capture parcel or pallet sizes and weights instantly.

- CRM – to manage customer relationships in the same ecosystem.

This integration means businesses no longer have to juggle between WMS, WCS, and other disconnected tools.

Affordable and User-Friendly

Traditional ERP and warehouse systems are expensive, hard to use, and slow to implement. Supply Chain Orchestrator provides enterprise-grade capabilities at about a third of the cost of large competitors, making it accessible to small and mid-sized companies without sacrificing functionality.

Built for the Future

With the latest cloud technologies, Supply Chain Orchestrator adapts to automation and AI-driven processes. Whether you’re running manual workflows today or planning to add robotics tomorrow, the platform scales with your growth and keeps your operations future-ready.

Conclusion: Optimize Your Warehouse with WCS + WMS

A warehouse control system (WCS) is essential for warehouses that rely on automation, while a warehouse management system (WMS) provides the oversight and data needed to manage inventory and fulfillment. On their own, each system has limitations—but together, they create a powerful combination that improves accuracy, reduces downtime, and drives efficiency.

Instead of struggling with multiple disconnected systems, businesses can now leverage Supply Chain Orchestrator—a modern platform that unifies WMS and WCS capabilities in one solution. With its cloud-based design, automation readiness, and affordable pricing, it gives warehouses the power to run faster, smarter, and more cost-effectively.

👉 Ready to streamline your warehouse operations?

Request a demo of Supply Chain Orchestrator today and see how you can achieve the efficiency of WMS + WCS in a single, easy-to-use platform.

Related Blogs

Cloud Based Inventory Management Systems for Smarter Supply Management

In today’s fast-moving supply chains, businesses need more than traditional tools to stay competitive. A modern inventory management solution—especially cloud based—is becoming essential for companies looking to moder...

Start Reading

How to Select the Best Warehouse Management System

Choosing the best warehouse management system for your supply chain operations can feel like a daunting task, especially when there are so many type of software out there. A good WMS is more than just software; it’s a...

Start Reading

What is Warehouse Automation? A Guide for Warehouse Managers

As a warehouse manager, you face the daily challenge of increasing productivity, reducing costs, and improving efficiency. Warehouse automation offers an exciting opportunity in this pursuit, but as with any new and i...

Start Reading